The Industrial Problem:

How to monitor the wear of refractory linings in boilers, furnaces and kilns during operation?

The REFRA-SENSE in-situ wear sensors offer continuous monitoring of the wear of your refractory lining at all times, live!

Major benefits of the use of REFRA-SENSE:

- Knowing at all times if there is enough refractory lining in your boiler or kiln

- Decrease of the production downtime during replacement the refractory lining in your kiln or boiler

- Have you ever wanted to be able to plan the maintenance times for your furnace or boiler?

Scientific and technological basis of operation of the Refra-Sense sensors

The Refra-Sense family of sensors works by monitoring the voltage across a metallic grid embedded in refractory mass, shaped as a thin brick (see figure above, the sensor itself is just visible in the front side) which is then built in the refractory wall, between two bricks (see figure below). As the refractory wears down during use, the embedded sensor wears down in tandem and the voltage change gives a direct measure of the amount of wear which is then displayed as depth of wear .

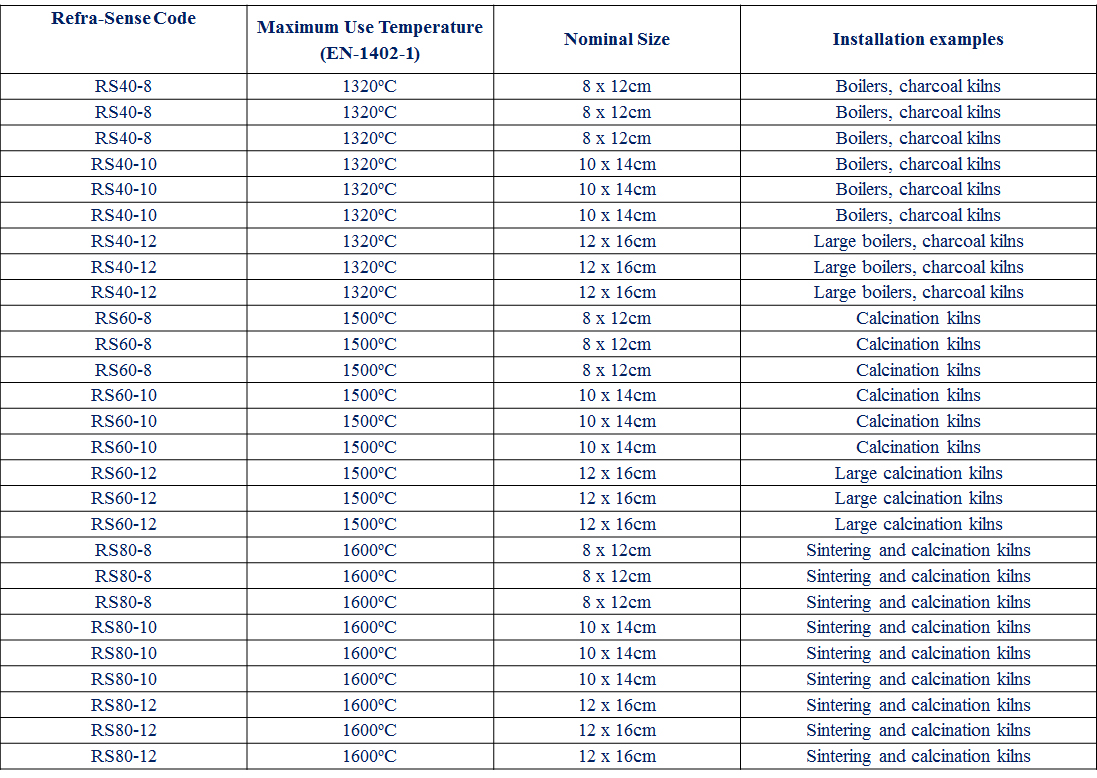

A REFRA-SENSE sensor for every application

All Refra-Sense sensors can be custom-fitted and retrofitted to nearly all types of kilns, furnaces and boilers. Three basic sizes of sensors have been developed which can be used with nearly all commercial refractory bricks up to 10x20x20cm in three refractory mass types corresponding to the three most popular gunning masses (EN 1402-1): 40 (Chamotte), 60 (Bauxite) and 80 (Alumina). Other sizes and types can easily be produced.

All types of Refra-Sense sensors are supplied as complete systems (embedded sensor, 50cm long ceramic (high alumina) tubing, electronics (220-240V) and a large red LED display) ready for installation in your kiln or boiler by any qualified refractory installer. No special electrical connections are necessary: just plug in and monitor the wear depth!

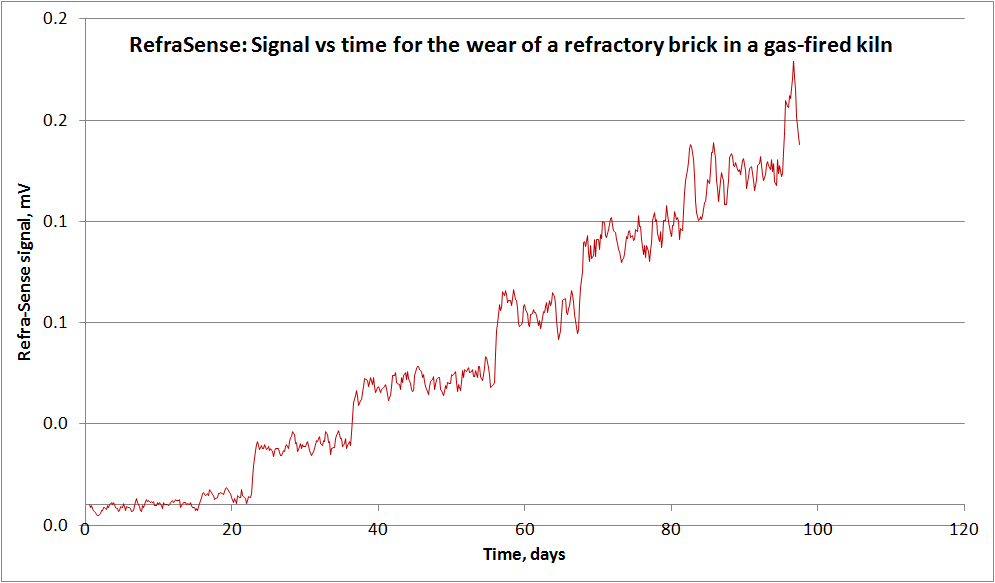

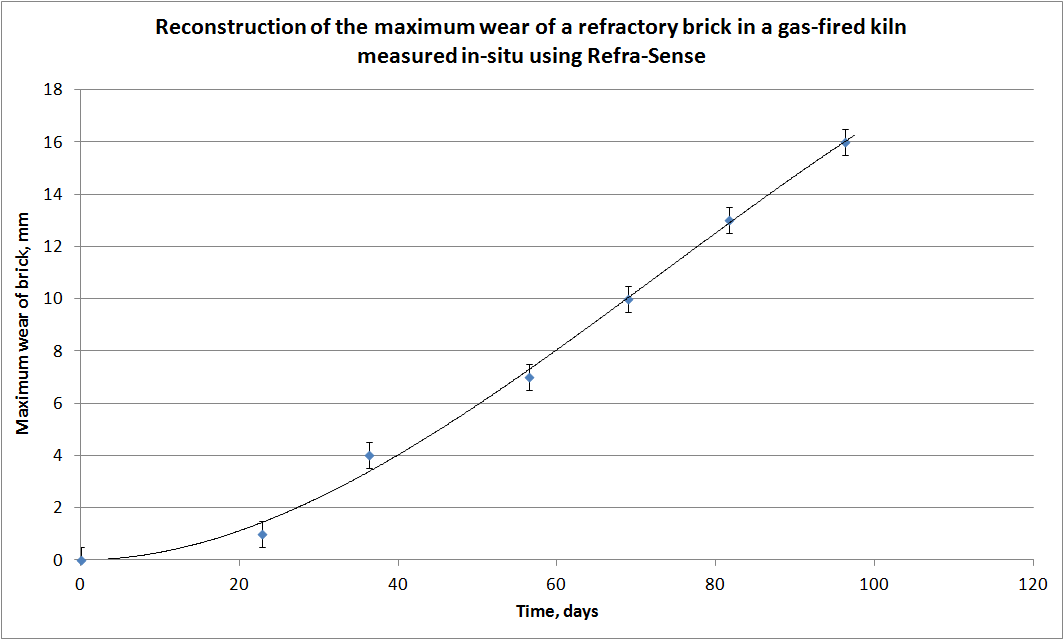

The sensor gives a signal over its whole width, about 10cm, and the signal corresponds to the deepest wear position. As an example, the signal over time curve for a gas-fired lab furnace burning continuously for over 3 months is shown in the figure on the right. The signal was recorded every 4 hours over the three months and the wear has been reconstructed and shown in the graph, bottom right. After a "slow" start for about 10 days when very little wear has occured, the wear of the brick proceeded approximately linearly over the 3 months and the final wear is shown in the photo below.

Specifications for all types of sensor systems and method of ordering

All Refra-Sense sensors can be supplied for single installation (single display) or for twin operation (double display). Please indicate whether you need single display or double display when ordering two or more sensors for a single installation.

A temperature sensor can also be embedded together with a Refra-Sense sensor – please indicate when ordering the sensor whether you wish to have a temperature sensor embedded with it. The temperature sensor is a type “K” thermocouple for sensor types RS40-X and type “S” thermocouple for all other types.

Industrial Installations

Refra-Sense sensors have already been installed in calcination kilns and boilers in Greece with excellent results! The kiln and boiler operators are now able to monitor the wear of their refractory lining at any time, allowing them to plan their maintenance schedule accurately and reliably!

A Refra-Sense sensor installed in the refractory

lining inside a large calcination kiln

near Kalamata, Greece.

A calcination kiln in Sparta, Greece

containing a double Refra-Sense sensor

with a thermometer and its display (inset above)

installed in a calcination kiln in Sparta, Greece.

For any further information, please contact us. We can produce a Refra-Sense sensor for most requirements – we are also open to any RD collaboration for further developments of Refra-Sense.