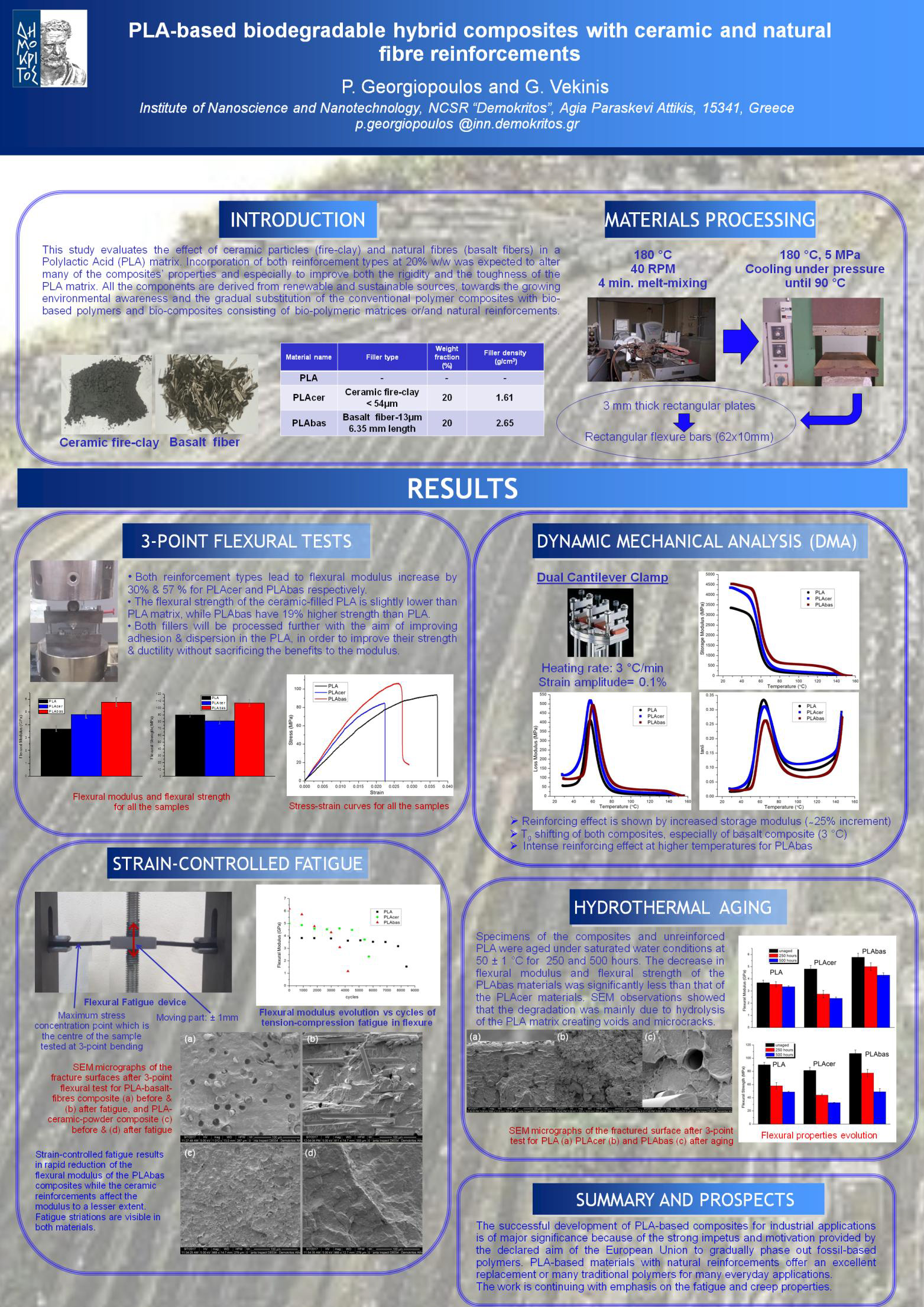

BIO-BASED, BIODEGRADEABLE POLYMER-CERAMIC COMPOSITES

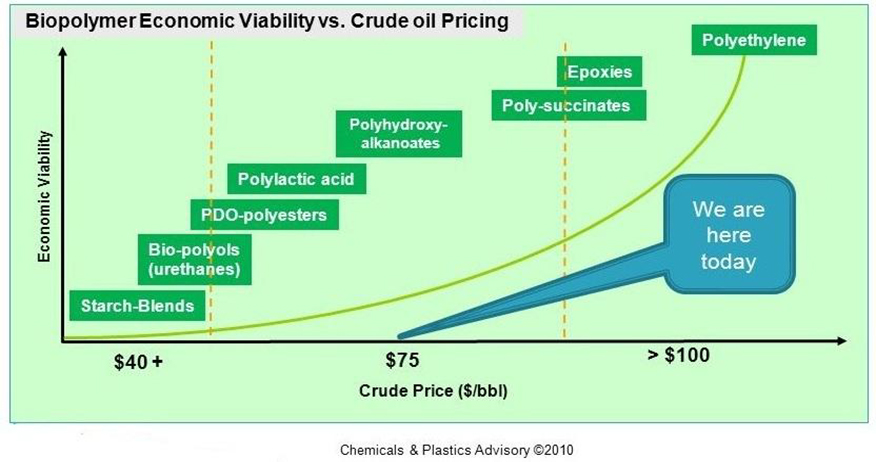

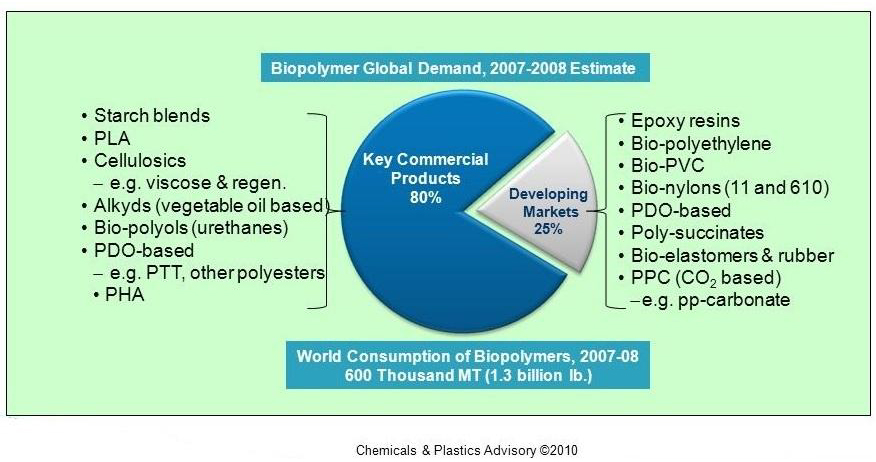

Bio-based, biodegradable polymer matrix composites are being developed as possible replacements for fossil-based polymers. As shown in the figures below, biopolymer economic viability relies on the cost of crude fossil oil which is expected to increase in the long run. In fact this is the most important industrial parameter for acceptance of biopolymers as they already display competitive performance in many (but not all) applications. Although biopolymer demand is still only a fraction of the total polymer demand worldwide, it is the fastest increasing part of the industry and the market. The highest demand biopolymers include starch-based, e.g. Poly Lactic Acid (PLA), cellulosics, polyesters and polyurethanes and the fields of application include, but not limited to medical devices, tissue engineering, packaging, consumer goods, automotive, gardening, 3D-printing, electronics, decoration, cosmetics, furniture and others.

Because of their melt-processable recyclability, bio-based thermoplastics are considered much more environmentally friendly than thermosets, such as resins. Biopolymer thermoplastics provide a unique mix of renewability and recyclability and therefore most of the global efforts in this area are made in this area.

Recently, the European Union has initiated a debate on the industrial efficacy of gradually replacing fossil-based polymer by bio-based ones, the eventual aim being to legislate a directive for the gradual phasing out of as many fossil-based polymers as possible.

PLA-based composites at the Advanced Ceramics and Composites Lab

Recently, the European Union has initiated a debate on the industrial efficacy of gradually replacing fossil-based polymer by bio-based ones, the eventual aim being to legislate a directive for the gradual phasing out of as many fossil-based polymers as possible.

PLA-based composites at the Advanced Ceramics and Composites Lab

PLA is an aliphatic polyester with the chemical formula (C3H4O2)n derived from corn starch, cassava roots, chips or starch or sugarcane. In 2010, PLA had the second highest consumption volume of any bioplastic of the world and this is increasing every year. Its density is 1.2-1.43g/cm3 (depending on method of manufacturing), glass transition temperature (GTT) 55-60oC, melting point 150-160oC and it is insoluble in water which allows its use in water-bearing applications. Its mechanical strength in bending at 25oC varies from 80-120MPa and its Young’s modulus in bending (rigidity) is 5-6GPa. The use of ceramic fillers and blending helps to increase the GTT and the mechanical properties of PLA, especially its toughness making it more suitable for critical applications where crack propagation must be avoided.As a result of the changing environmental priorities on fossil-based polymers, the Advanced Ceramics and Composites Lab has decided to make the development of PLA-based composites a major objective with particular emphasis on the use of PLA as a matrix reinforced by ceramic powders or fibres. Our research is centred on starch-derived Poly Lactic Acid (PLA) which has shown very considerable promise for use in a very large spectrum of applications while its price is very competitive already (2016) to fossil-derived polymers.

PLA has competitive mechanical and physical properties to conventional fossil-based polymers and is compostable. Its main advantage is the potential for short-life applications due to its ability to degrade under above normal environmental conditions, but its market is turning from "disposable" to "durable" due to its robustness in normal conditions. This means that it can be used for ordinary applications where it will degrade very slowly.

Over the past years we have been experimenting with the incorporation of high-modulus ceramic short fibers or particles into the PLA matrix in order to improve several properties of the material. Our research is focusing on

o Material processing strategies and optimization

o Effect of reinforcement type/content and matrix-filler bonding issues on the mechanical properties of the composites

o Long-term stability and environmental aging

with a view towards being able to eventually tailor its material properties for new applications.

Our work has been presented at the EuroMat2017 conference (right) and other conferences.