SHS / SCS

Synthesis of materials by controlled combustion

Synthesis of materials by controlled combustion techniques (combustion synthesis) is now recognised as a very promising route since most of the synthesised materials - in many cases - much better properties and performance than the same materials produced by traditional methods. At the same time, production cost is lower and production time is much faster.

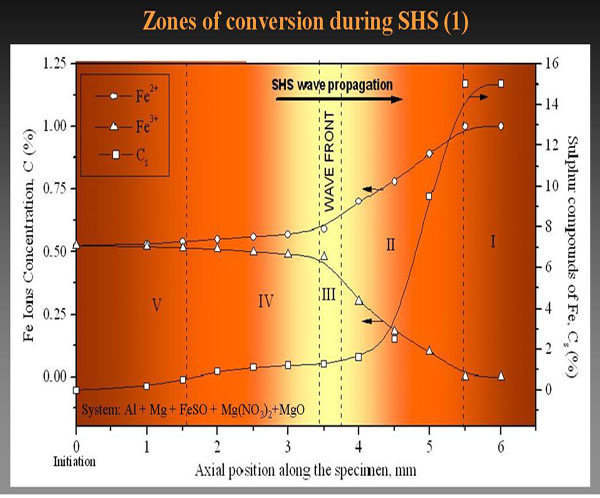

Combustion synthesis relies on exothermic reactions between powders in a compact which drives the synthesis - very high heating and cooling rates are possible while the environment can be kept at lower temperatures or even room (see SHS reaction zones chartright, bottom).

Two main categories of combustion synthesis are being studied in our laboratory for materials synthesis. For solid materials, we use the Self-propagating High temperature synthesis (SHS) route (diagram and left video right) which is able to produce a large range of materials with excellent properties, including refractories, catalysts with very high density of active centres, intermetallics, pigments etc (see chart below). For high purity nanoparticles, the Solution Combustion Synthesis (SCS) method has been developed with a range of applications (see video, far right).

The current research activites of the laboratory for synthesis of materials using combustion methods are concentrated on the following fields:

1) Studies of the SHS and SCS kinetics and themodynamics.

2) Synthesis of new catalytic materials for environmental protection and production of new high-value chemicals. A very large range of SHS and SCS catalysts have been developed for many applications.

3) Development of new inorganic pigments for use in ceramics, plastics, paper industries etc (below right)

4) Studies of in-situ SHS bonding of difficult HT materials such as SiC, MgO and others (below)

5) Development of new HT refractories in the Mg-Al-O system for applications such thermal protection of spacecraft

6) Development of new recycling methods of solid wastes (slags, fly-ash, steel wastes) by SHS- incorporation in construction materials

A very important activity which is lately under development in our laboratory is the innovative method for coating metals 'CAFSY' (Combustion-aided flame spraying) for producing hard coatings on metals of intermetallic protective phases (see figure below and video). CAFSY combines oxyacetylene Flame spraying with SHS and offers the possibility of cheap, hard coatings of intermetallic systems such as NiAl etc for the mechanical and corrossion protection of axles, blades etc, with a method that is almost as good as plasma spraying but at a much lower cost..

A major industrial advantage of the CAFSY method is the capability it offers for in-situ repairs of machinery and equipment at very low cost. In the video above, the SHS reaction between Ni and Al is clearly visible in the flame.